Accessories

We complement the fill line with all relevant accessories and custom built to meet your production needs.

We study the best option for your company, giving it the best possible value for money. If you have questions about our equipment, contact us.

We at Envasquim, S.L. have a standardized manufacturing system for filling, sealing machines and processing equipment. From this base, we manufacture our equipment fully customized to your needs.

Depending on the volume of manufacture or packaging, placement, automation capabilities required, desired production and characteristics of product packaging, we will study the best option for your company giving you the best value possible.

The use of our own technologies which are under constant evolution make our company a reliable and guaranteed after-sales service, always following the project beyond its delivery.

Our equipment is made of European materials of leading brands to ensure maximum reliability in the machines and the right amount of suitable stock.

The confidence in our equipment allows us to give a two year warranty against manufacturing defects on all our equipment.

We complement the fill line with all relevant accessories and custom built to meet your production needs.

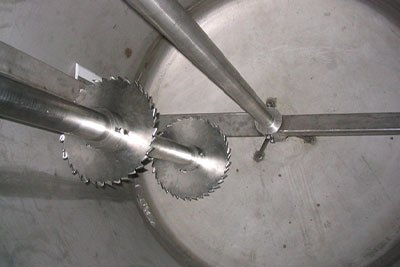

Products prepared for agitation, dispersion or broken products in all dimensions and for all types of products.

Equipment for manufacturing preparations of cosmetics, chemicals gels or creams.

Check out the different filling systems.

Complement the fill line with all relevant accessories and custom built to meet your production needs.

Carafe fillers prepared for filling from 5 liters.

Linear filler nozzle one quick adjustment between formats.

Fillers oriented desktop for low filling productions.

Filling prepared and designed for quick and easy changeover.

Filling prepared and designed to cover a wide range of packaging designs, from small containers up to 10 liters.

Consult with us the specifications of your project, Depending on the volume to be manufactured or packaged, its location possibilities, required automation capacity, desired production, characteristics of the containers and product, we advise you on the best solution for your company.