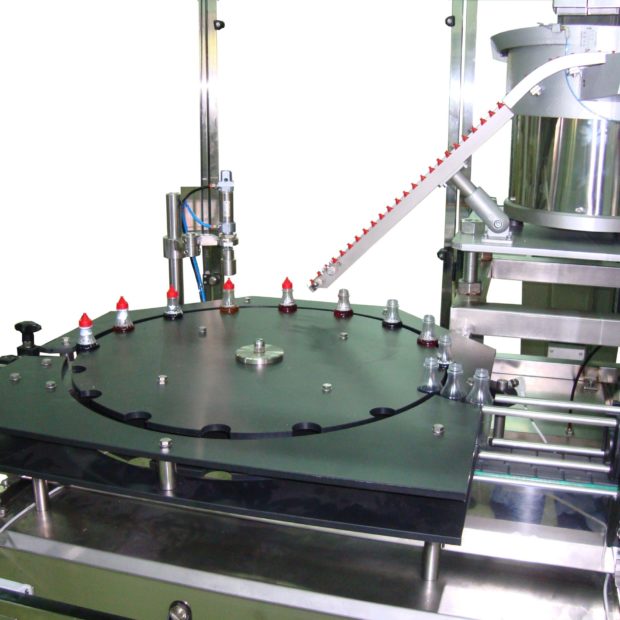

Filling prepared and designed for quick and easy changeover. Easy adjustment formatting changes without tools, allowing for easy cleaning construction of the filling system.

Our fillers are especially recommended cosmetics and packaging with stability issues or for dispensing small amounts as vials, ensuring correct dosage and easy handling when adjusting small packages.

All our rotary fillers alternatives.

They can be made from 1-6 filling nozzles covering a maximum output of 4,000 hours.

Depending on the output you require, the degree of automation required, fill volume and type of product to be handled, we will advise the best filling system.

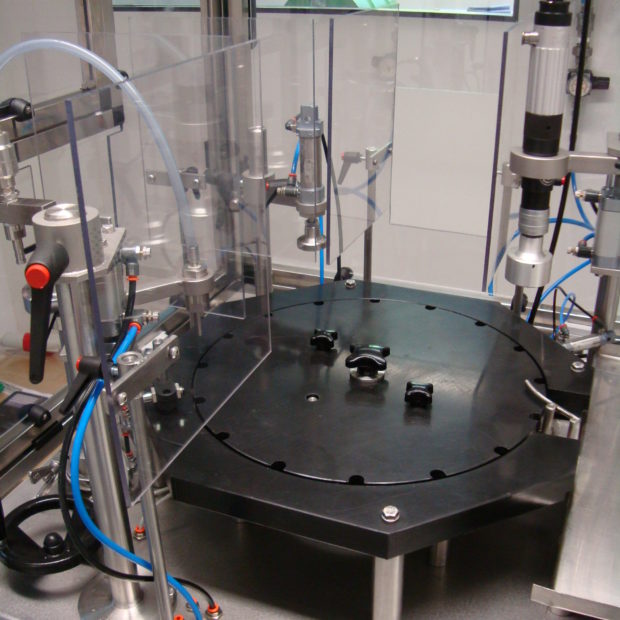

Our seamers are constructed and designed depending on the type of cap, the desired production and stability of the containers, then deriving a linear or a rotary system.

Our seamers can come with automatic positioner type plugs theft or pick and place type, with automatic lifting caps providing greater autonomy to the system and minimal supervision.

Also depending on the features of your product, we advise seamer type best suits your features.

Seamers rotary fillers are also constructed in Ex version

Applications of ROTARY FILLERS SEAMERS

All our products may be used in the following professional fields:

Request your budget

Or do your query